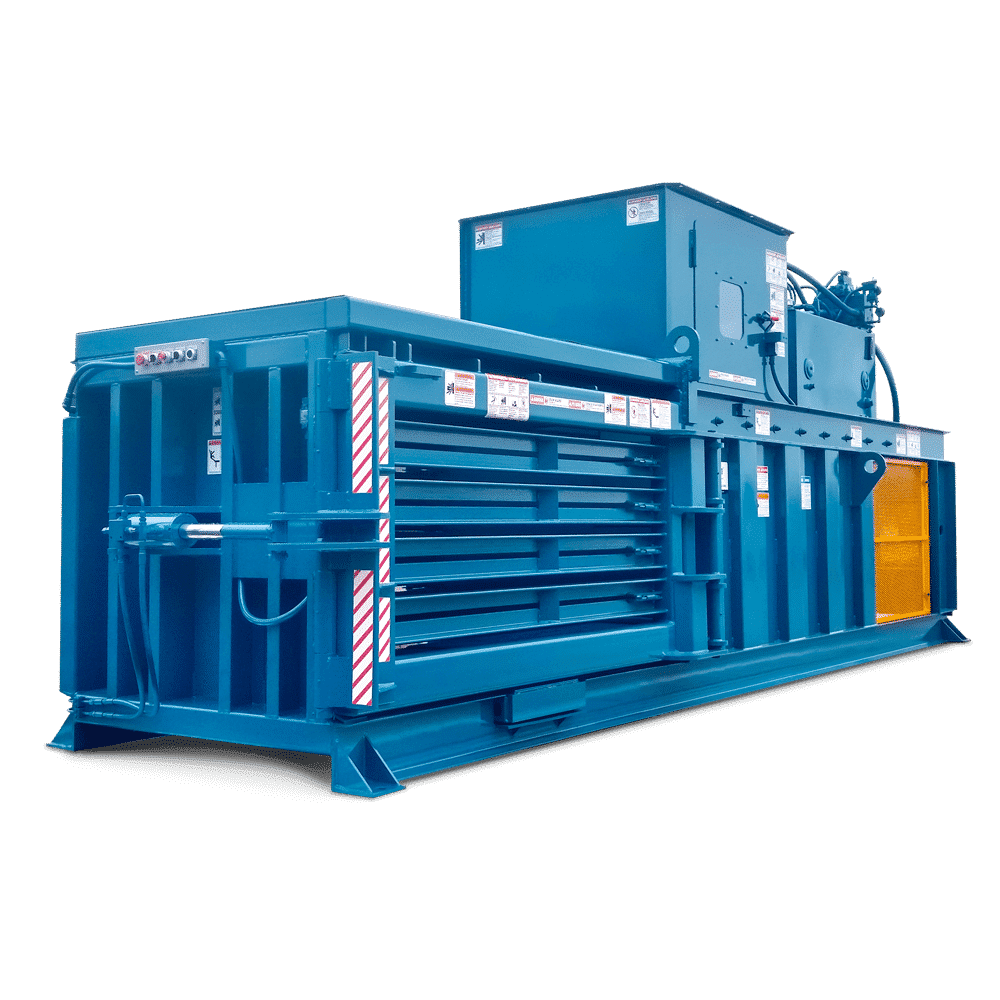

Marathon Side Eject Horizontal Balers

The Marathon® patented line of Side-Eject Horizontal Recycling Balers are uniquely engineered to maximize productivity. They include many features not found on conventional closed-end balers:

- Switch recyclables without contamination and maximize the value of your product

- Minimize spillage between bales and reduce the need to “double handle” materials

- Remove finished bales quickly and automatically to improve efficiency

- Front bale tie off saves valuable floor space and eliminates trips behind the baler

- Increased product value by eliminating contamination between bales as the operator changes materials being processed.

- Maximum and consistent bale weights with the Marathon Bale Made Indicator, which signals that the bale is finished. No time consuming “flag pole” or manual measuring device to compromise bale quality.

- The Marathon exclusive front bale tie-off system allows the operator to quickly direct tie wires around the bale from the front of the baler. This eliminates the need to go behind the baler and loosen hanging wires that drag as a bale is made.

- Dramatically reduces spillage commonly found with conventional balers. No need to “double handle” materials being processed.

- Remove each bale from the bale chamber quickly and easily with the patented Marathon Side-Eject feature and Bale Server Island. Unlike conventional balers that require an operator and forklift to free the bale from the end of the bale chamber, the Marathon Side-Eject design provides consistent and complete bale ejection every time.

Please contact one of the EMP Partner(s) below: