Aggressive Hydraulics 800 Series Cylinders Heavy-Duty Hydraulic Cylinders (3,000 psi)

- Clevis style base and rod mounts

- 3000 PSI Heavy Duty Type

- Cold drawn (high impact) 75,000 min.yield D.O.M. tubing

- Ground & polished, hard chrome plated rods (75,000 min. yield)

- Welded style construction certified to A.W.S. B2.1

- Internally threaded head design with buttress threads

- Highest quality seal configurations compatible with petroleum base fluids

- Increased bearing length on both head & piston

- Ductile iron head gland & piston

- Piston utilizes wear bearings

- Nylon inserted lock nut

- Standard paint; black primer

- Try the Aggressive Hydraulics Pre-Engineered Cylinder Drawing Program

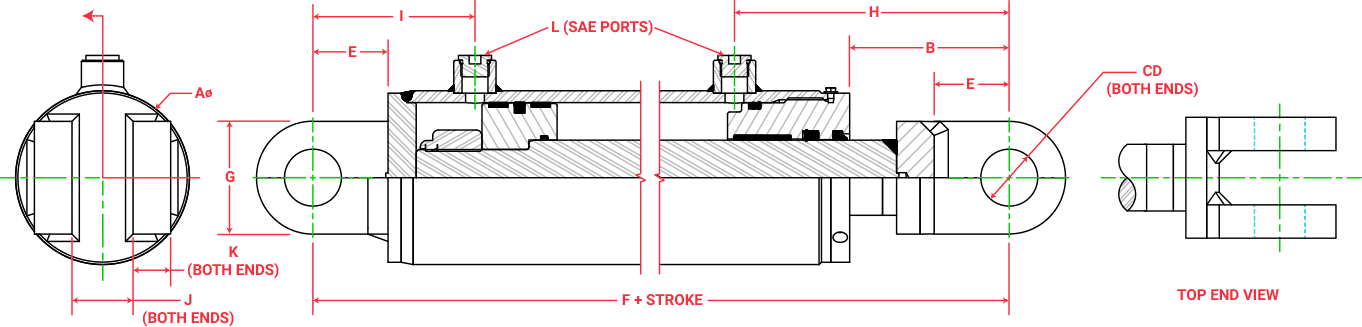

| Bore | Rod | A | B | CD | E | F | G | H | I | J | K | L | Part # |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3.00 | 1.75 | 3.50 | 3.31 | 1.000 | 2.00 | 12.00 | 2.00 | 5.75 | 3.94 | 1.25 | .50 | #6 | 804-**.** |

| 2.00 | 3.50 | 3.31 | 1.000 | 2.00 | 12.00 | 2.00 | 5.75 | 3.94 | 1.25 | .50 | #6 | 806-**.** | |

| 3.50 | 1.75 | 4.00 | 3.81 | 1.250 | 2.00 | 12.50 | 2.50 | 4.50 | 4.50 | 1.62 | .75 | #8 | 810-**.** |

| 2.00 | 4.00 | 3.50 | 1.250 | 2.00 | 12.50 | 2.50 | 5.94 | 4.69 | 1.62 | .75 | #8 | 812-**.** | |

| 4.00 | 2.00 | 4.62 | 4.25 | 1.500 | 2.00 | 14.00 | 3.00 | 7.31 | 4.31 | 1.62 | 1.00 | #8 | 816-**.** |

| 2.50 | 4.62 | 4.25 | 1.500 | 2.00 | 14.00 | 3.00 | 7.31 | 4.31 | 1.62 | 1.00 | #8 | 818-**.** | |

| 3.00 | 4.62 | 4.12 | 1.500 | 2.00 | 14.50 | 3.00 | 7.94 | 4.56 | 1.62 | 1.00 | #8 | 820-**.** | |

| 4.50 | 2.00 | 5.12 | 4.25 | 1.500 | 2.00 | 14.25 | 3.00 | 7.38 | 4.50 | 1.62 | 1.00 | #10 | 824-**.** |

| 2.50 | 5.12 | 4.00 | 1.500 | 2.00 | 14.25 | 3.00 | 7.12 | 4.75 | 1.62 | 1.00 | #10 | 826-**.** | |

| 3.00 | 5.12 | 4.00 | 1.500 | 2.00 | 14.25 | 3.00 | 7.12 | 4.75 | 1.62 | 1.00 | #10 | 828-**.** | |

| 3.50 | 5.12 | 4.00 | 1.500 | 2.00 | 14.50 | 3.00 | 7.88 | 4.62 | 1.62 | 1.00 | #10 | 830-**.** | |

| 5.00 | 2.00 | 5.62 | 4.25 | 1.750 | 2.25 | 14.25 | 3.50 | 7.19 | 4.69 | 2.12 | 1.00 | #12 | 834-**.** |

| 2.50 | 5.62 | 4.12 | 1.750 | 2.25 | 15.00 | 3.50 | 7.50 | 4.94 | 2.12 | 1.00 | #12 | 836-**.** | |

| 3.00 | 5.62 | 4.12 | 1.750 | 2.25 | 15.00 | 3.50 | 7.50 | 4.94 | 2.12 | 1.00 | #12 | 838-**.** | |

| 3.50 | 5.62 | 4.25 | 1.750 | 2.25 | 15.00 | 3.50 | 7.62 | 4.81 | 2.12 | 1.00 | #12 | 840-**.** | |

| 4.00 | 5.62 | 4.12 | 1.750 | 2.25 | 15.00 | 3.50 | 8.06 | 4.94 | 2.12 | 1.00 | #12 | 842-**.** | |

| 5.50 | 2.50 | 6.12 | 4.44 | 1.750 | 2.25 | 15.50 | 3.50 | 7.81 | 5.00 | 2.12 | 1.25 | #12 | 846-**.** |

| 3.00 | 6.12 | 4.56 | 1.750 | 2.25 | 15.50 | 3.50 | 7.94 | 4.88 | 2.12 | 1.25 | #12 | 848-**.** | |

| 3.50 | 6.12 | 4.56 | 1.750 | 2.25 | 15.50 | 3.50 | 7.94 | 4.88 | 2.12 | 1.25 | #12 | 850-**.** | |

| 4.00 | 6.12 | 4.44 | 1.750 | 2.25 | 15.50 | 3.50 | 7.81 | 5.00 | 2.12 | 1.25 | #12 | 852-**.** | |

| 4.50 | 6.12 | 4.56 | 1.750 | 2.25 | 16.25 | 3.50 | 8.50 | 5.63 | 2.12 | 1.25 | #12 | 854-**.** | |

| 6.00 | 2.50 | 6.75 | 4.62 | 2.000 | 2.50 | 16.00 | 4.00 | 8.00 | 5.31 | 2.62 | 1.25 | #12 | 858-**.** |

| 3.00 | 6.75 | 4.50 | 2.000 | 2.50 | 15.75 | 4.00 | 7.88 | 5.19 | 2.62 | 1.25 | #12 | 860-**.** | |

| 3.50 | 6.75 | 4.50 | 2.000 | 2.50 | 15.75 | 4.00 | 7.88 | 5.19 | 2.62 | 1.25 | #12 | 862-**.** | |

| 4.00 | 6.75 | 4.62 | 2.000 | 2.50 | 16.00 | 4.00 | 8.00 | 5.31 | 2.62 | 1.25 | #12 | 864-**.** | |

| 7.00 | 2.50 | 8.00 | 5.19 | 2.500 | 3.00 | 17.75 | 5.00 | 9.12 | 5.75 | 2.62 | 1.25 | #16 | 868-**.** |

| 3.00 | 8.00 | 5.19 | 2.500 | 3.00 | 17.75 | 5.00 | 9.12 | 5.75 | 2.62 | 1.25 | #16 | 870-**.** | |

| 3.50 | 8.00 | 5.19 | 2.500 | 3.00 | 17.75 | 5.00 | 9.12 | 5.75 | 2.62 | 1.25 | #16 | 872-**.** | |

| 4.00 | 8.00 | 5.06 | 2.500 | 3.00 | 18.25 | 5.00 | 9.00 | 6.38 | 2.62 | 1.25 | #16 | 874-**.** | |

| 8.00 | 3.50 | 9.00 | 6.50 | 3.000 | 4.00 | 22.00 | 6.00 | 10.69 | 7.44 | 3.12 | 1.50 | #16 | 878-**.** |

| 4.00 | 9.00 | 6.50 | 3.000 | 4.00 | 22.00 | 6.00 | 10.69 | 7.44 | 3.12 | 1.50 | #16 | 880-**.** | |

| 4.50 | 9.00 | 6.50 | 3.000 | 4.00 | 22.00 | 6.00 | 10.69 | 7.44 | 3.12 | 1.50 | #16 | 882-**.** |

All Pre-engineered Cylinders are manufactured in the U.S.A. and are backed by the Aggressive Hydraulics Cylinder Warranty.

- To complete part#; replace (**.**) with stroke required

- Maximum allowable stroke length for a given model is dependent on the actual maximum operating pressure and compressive load. Buckling strength limit for a cylinder will be calculated at the time of initial order or upon customer request.

- Other port sizes and locations are available upon request

- Consult factory for longer stroke and or higher pressure applications

Please contact one of the EMP Partner(s) below:

Aggressive Hydraulics (HQ)

Call: (763) 792-4000

18800 Ulysses Street Northeast

East Bethel, Minnesota