Galfab, Standard Duty Hoists, Inside/Outside Rail Hoist (IO Series)

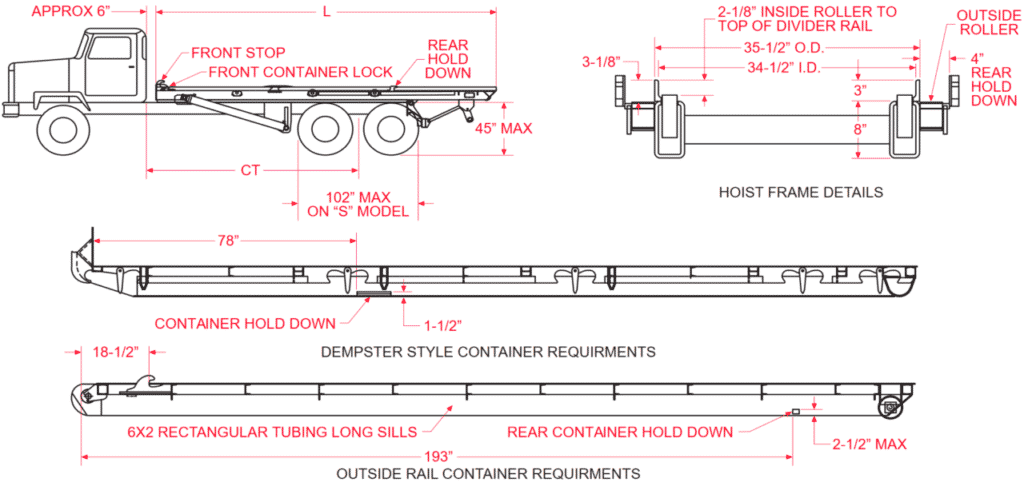

The Inside/Outside Rail roll-off hoist has the versatility to pick up inside and outside rail containers and comes standard with inside rollers. This hoist has a Cor-Ten divider rail and inside rollers for the inside rail containers. This hoist is also offered with an 8” mainframe and 2” subframe and the 10” sub frameless hoist. Available in 60k and 75k pound models to fit any application.

- 8″ x 4 x 1/2″ Main Frame Tube

- 3″ x 3″ x 1/2″ Cor Ten Top Divider Angle

- 3″ x 2″ x 1/4″ Subframe

- 2 1/2″ Diameter Rear Hinge

- All Working Points Greaseable

- Pintle Ready Apron

- Auto Fold Forward DOT Bumper

- 1″ Spring Loaded Container Locks

- 2 1/2″ Diameter Lift Cylinder Shafts

- Interchangeable 10″ Vertical and Horizontal Sheaves

- 3/8 inch x 3-inch Winch Cylinder Rod Covers

- 6 Inboard and Outboard Supported Outside Rollers

- Container Long Sill Supports on Rear of Hoist Mainframe

- 48 Gallon Oil Reservoir with Sight and Temperature Gauge

- 25 Micron Filtration

- Inside and Outside Controls

- Choice of Forward or Reverse Mount Single-Stage or Telescopic Lift Cylinders

- LED Lighting System

- 7/8” Cable with Heavy Duty Swivel Eye Hook

- Galfab Auto-Fold DOT bumper

- Front Mount Pump

- Hoist Up Warning Light

- 4 Inside Rollers

- Hoist Up Alarm

- Backup Alarm

- Behind Cab and Oversize Oil Tanks

- Tool Boxes

- Auxiliary Stops

- Poly or Steel Fenders

- Aluminum Fenders

- Tarping Systems

- Hooker Hold On Systems

- Ratchet Tie Down Straps

- PTO

- Drop Shaft

- Integrated hydraulics can be used if hydraulic tarping system is used

- Rear View Camera Systems

- Work Lights

- Onboard Scale Systems

| Model | Capacity | CA | CA with tarp | Length | Dump Agle | Up (sec)* | Down (sec)* | On (sec)* | Off (sec)* | Lift Cylinder | Winch Cylinder | Container Length ft | Apx Weight lbs |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IO60174S072 | 60,000 | 174″ | 186″ | 23’3″ | 48° | 27 | 15 | 41 | 28 | 6″ x 4″ x 72″ DA | 7″ x 4″ x 79.5″ DA | 18′-22′ | 7550 |

| IO60174S072R | 60,000 | 174″ | 186″ | 23’3″ | 48° | 27 | 15 | 41 | 28 | 6″ x 4″ x 72″ DA | 7″ x 4″ x 79.5″ DA | 18′-22′ | 7550 |

| IO60174T121 | 60,000 | 174″ | 186″ | 23’3″ | 48° | 35 | 29 | 41 | 28 | 6″-5″-4″ x 121″ DAT | 7″ x 4″ x 79.5″ DA | 18′-22′ | 7225 |

| IO75174S072F7 | 75,000 | 174″ | 186″ | 23’3″ | 48° | 37 | 23 | 41 | 28 | 7″ x 4″ x 72″ DA | 7″ x 4″ x 79.5″ DA | 18′-22′ | 7550 |

| IO75174S072R7 | 75,000 | 174″ | 186″ | 23’3″ | 48° | 37 | 23 | 41 | 28 | 7″ x 4″ x 72″ DA | 7″ x 4″ x 79.5″ DA | 18′-22′ | 7550 |

| IO75174T121 | 75,000 | 174″ | 186″ | 23’3″ | 48° | 35 | 29 | 41 | 28 | 6″-5″-4″ x 121″ DAT | 7″ x 4″ x 79.5″ DA | 18′-22′ | 7350 |

| IO60194S072 | 60,000 | 194″ | 206″ | 24’11” | 48° | 27 | 15 | 46 | 31 | 6″ x 4″ x 72″ DA | 7″ x 4″ x 89.5″ DA | 20′-24′ | 7850 |

| IO60194S072R | 60,000 | 194″ | 206″ | 24’11” | 48° | 27 | 15 | 46 | 31 | 6″ x 4″ x 72″ DA | 7″ x 4″ x 89.5″ DA | 20′-24′ | 7850 |

| IO60194T121 | 60,000 | 194″ | 206″ | 24’11” | 48° | 35 | 29 | 46 | 31 | 6″-5″-4″ x 121″ DAT | 7″ x 4″ x 89.5″ DA | 20′-24′ | 8075 |

| IO75194S072F7 | 75,000 | 194″ | 206″ | 24’11” | 48° | 37 | 23 | 46 | 31 | 7″ x 4″ x 72″ DA | 7″ x 4″ x 89.5″ DA | 20′-24′ | 7850 |

| IO75194S072R7 | 75,000 | 194″ | 206″ | 24’11” | 48° | 37 | 23 | 46 | 31 | 7″ x 4″ x 72″ DA | 7″ x 4″ x 89.5″ DA | 20′-24′ | 7850 |

| IO75194T121 | 75,000 | 194″ | 206″ | 24’11” | 48° | 35 | 29 | 46 | 31 | 6″-5″-4″ x 121″ DAT | 7″ x 4″ x 89.5″ DA | 20′-24′ | 8075 |

* Cycle Times are Factory developed and controlled by PTO output, oil viscosity, human and mechanical efficiency, and may vary accordingly.

CAUTION: This Equipment Should be Operated by Properly Trained Personnel. Improper Use, Misuse, or Lack of Maintenance Could Cause Injury to Persons or Property. Photos used in this brochure are illustrative only. We reserve the right to make changes at any time without notice. Information contained within this literature is believed to be the most accurate available at the time of printing.