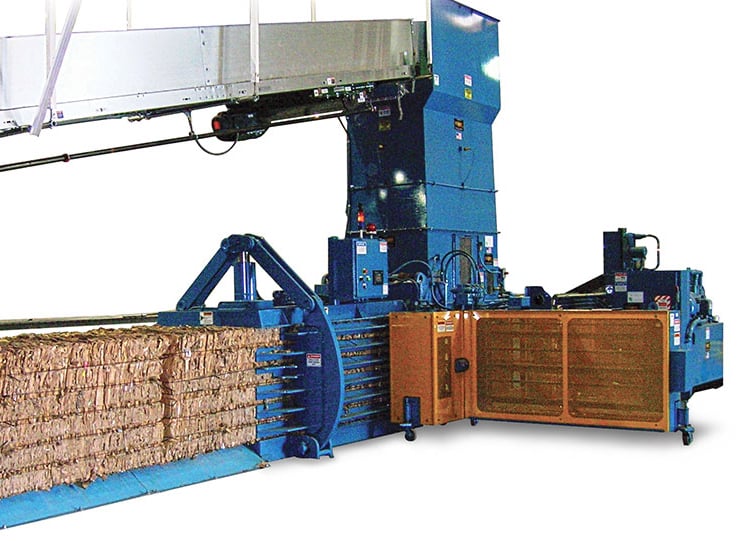

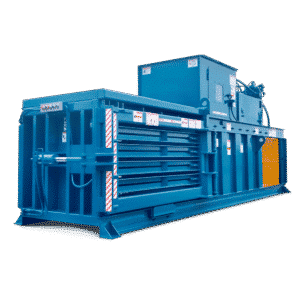

Marathon TIEger Auto-Tie Horizontal Baler

Marathon’s TIEger Auto-Tie Horizontal Baler uses highly efficient gear twisters, which eliminates pigtails. This accounts for more than 10% reduction in wire consumption and related costs. The gear twisters and inserter needles are hydraulically driven and wire is dispensed directly from our unique box holders. Hydraulic wire positioners precisely align the wires for pick-up by the inserter needles, making the TIEger the most reliable tier on the market.

Marathon auto-tie balers are designed for high productivity and ease of use with advanced electronics, such as the Allen-Bradley MicroLogix 1500 PLC and Maestro® color touch-screen operator interface. From this interface, the operator can control a variety of baler functions such as auto and manual modes, bale settings, system pressure, bale length, and perform computerized diagnostics. The main panel box features IEC controls.

- Single-cylinder tension system, which leverages and generates force on all four sides

- All pivot points have solid steel bushings and grease fittings

- Adjustable Nylatron® inserter needle positioners (on the side opposite the tie) maintain correct needle position

- Inserter and twister assembly cabinet pivots for easy access and maintenance

- Inserters and gear twisters are driven by hydraulic motors

- Hydraulic wire positioners

- Bolt-in shear blades are replaceable (NS, WS and EWS only)

- 500 Brinell steel liners on the floor and ram bottom.

- Chute-type feed hopper with gasketed access door with viewing windows on both sides of the baler.

- Oversized ram hold-down bars are adjustable from the exterior of the machine.

- Heavy duty, spring-loaded retainer locks

- Wire box holders make loading quick and easy with no adjustment required. ceramic wire guides and adjustable wire rollers

- Optional wire run-out system available

- Spring-loaded counter wheel located on the side of the baler sends digital bale length reading to the operator interface

- Maestro® color touch screen operator interface with Allen-Bradley Micrologix 1500 Plc; provides many functions such as diagnostics, bale set-up, bale length, and system pressure

- Infrared photo electric sensors are adjustable to the entire height of the hopper door window

- UL® and CUL® listed control systems

- Start-up alarm and beacon

- 460V/3-phase/60Hz high-efficiency power unit

- Power packs up to 150HP (dual motor units available)

- Lockable main circuit breaker

- Low-oil shutdown switch, high oil temperature shutdown switch, and oil shut-off valve

- Quiet running pump system

- Electrically actuated regen hydraulic system

- Current and pressure transducers standard

- Air-to-oil cooler

- 150 to 600 gallon hydraulic oil reservoir (up to 200 gallons delivered with the unit)